EXPLAINED! GENESIS Short Block Assembly.

If you have ever wondered what was the difference with the Tomei Genesis Shortblock assemblies and others, well now we will go into the brief details of our products.

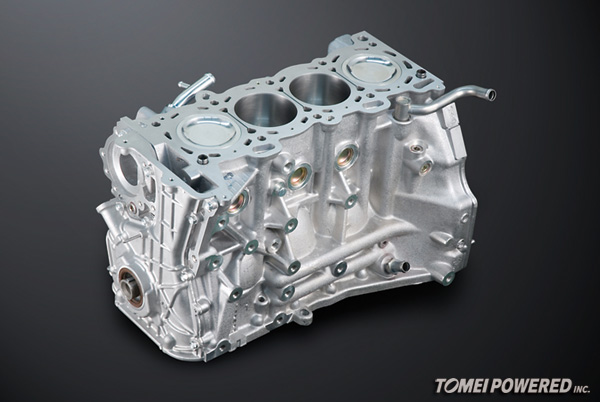

The assembly above is of the Nissan RB28SB Short Block Assembly.

This is the Nissan SR22 Short Block Assembly. Available in 2 options. One for the S13, and the other for both the S14 & S15 applications.

This is the Mitsubishi 4G63 Short Block Assembly. Available in 4 options.

2.2L for EVO 8

2.2L for EVO 9

2.3L for EVO 8

2.3L for EVO 9

This is the Subaru EJ22 Short Block Assembly. Available in 2.2L option.

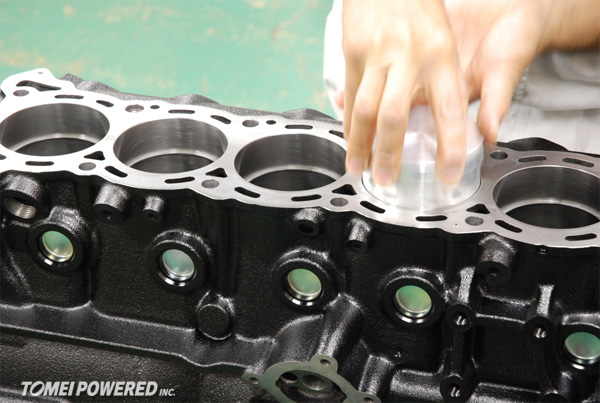

So now to know how we build these assemblies, let’s take a quick look at the build process here at Tomei Japan. The following is the main processes, naturally there are a bit more Tomei secrets involved. Everything is also painstakingly logged and archived for each and every assembly. That way, if there was any need to, we can always go back and look into any details that we need to find out about any assembly.

CYLINDER BLOCK SURFACE CORRECTION

The blocks surface is milled and the central part cavities are corrected down to the finest details. The heads meting face is increased for accurate optimum sealing characteristics. The block is then prepared for the boring & honing process.

BORING & HONING WITH DUMMY CYLINDER HEAD

The dummy head is fitted to the block to replicate the complete engine assembled for the boring and honing process. This maintains the highest levels of accuracy for the cylinder bore. Honing is processed to reduce friction and increase oil accumulation which helps maintain the tightest piston clearances. All measurements and assembly is performed in a temperature controlled room of 20±1℃. all year round.

REMOVING CASTING ERRORS

The excess casting errors that remain from the factory cast finish, can come off & run through the engine system. This can cause major problems. This important detail must not be missed to remove all unwanted casting burr from the blocks surface & maximize your engines life.

COMPLETE CLEANING & INSPECTION

The high pressure washing & air cleaning are all performed with meticulous detail. The extensive 3 step process is performed in detail with the oil galleries and water jackets. Everything is inspected on the new block to find any faults from the original factory casting for fault lines. Any casting burrs and/or irregularities are then corrected and/or removed.

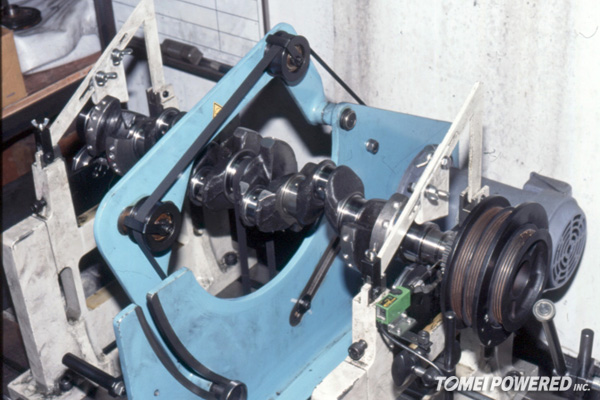

CRANKSHAFT DYNAMIC BALANCING

The dynamic balancing of the crankshaft reduces unwanted vibrations & increases response, engine speed, extends bearing & engine life for additional power gains. This process optimizes the crankshafts optimum potential.

PISTONS & CONRODS BALANCING

Since the rotating assembly will be used for high engine speeds and extreme conditions, the stress loads will be excessive as well. With the high inertial forces experienced by these components the G-Forces can be up to 2000G so with a tiny difference in weight at those conditions will be a major factor for uneven wear, distortion, performance and engine life. So precision and accuracy with zero or bare minimal weight difference across all components is an absolute must to get the most out of your engine.

MAINS & CONROD BEARING MATCHING

Minimizing friction and increasing lubrication efficiency is optimized by maintaining consistent strict clearances. Both the TOMEI Conrods and TOMEI competition Bearings have been designed to for the best results in minimizing metal fatigue & scoring while improving durability for high power and RPM applications.

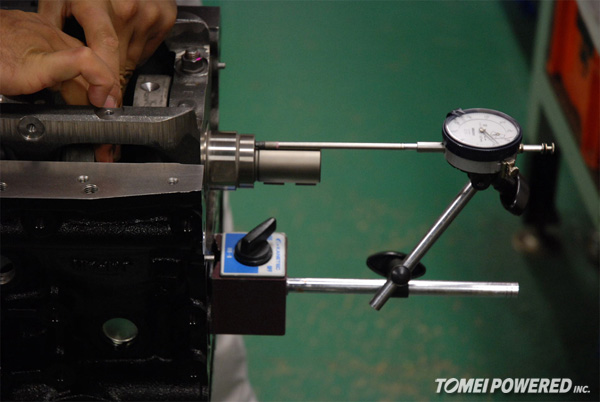

CRANK & CONROD THRUST CHECK

Both the Crankshaft & Connecting Rods thrust clearance is checked and kept within the specified values required.

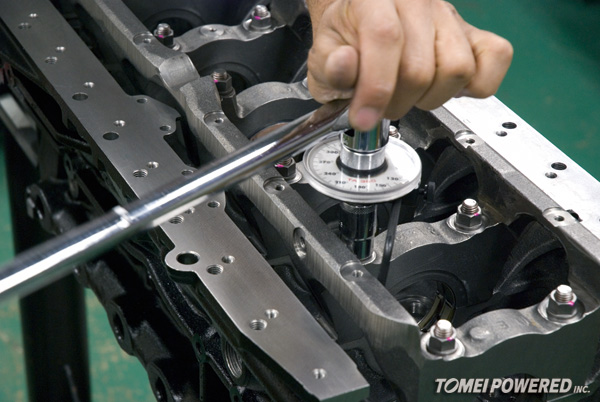

PRECISION ASSEMBLY

Each & every TOMEI Complete Engine Product has been assembled by TOMEI strict engine build processes. Precise, strict tolerances & clearances are all meticulously checked & maintained. All studs/bolts have assembly paste applied; torque settings are checked & performed twice on each & finally tightened with the angle wrench gauge.

ACCESSORIES

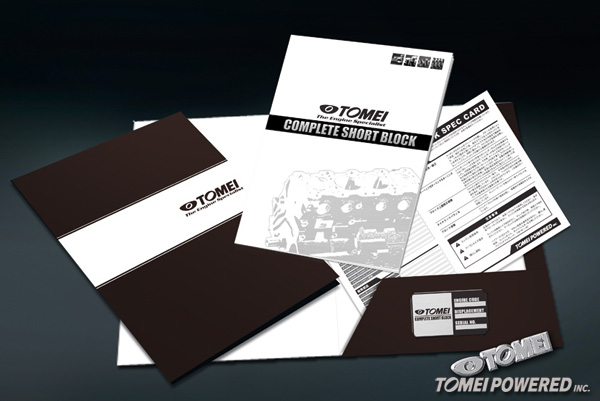

SERIAL PLATE

A special TOMEI Serial number is linked with the engine and the manual provided.

*NOTE: The serial plate (as shown above) is will have the details on it that matches the assembly that it comes with. This photo is a blank plate for illustration purposes only.

SPEC CARD

Clearly specifies the main parts and specs for reference on your future rebuilds.

PRODUCT MANUAL

Explanation book detailing the parts & build process to give you the inside view of the technical power of TOMEI.

EMBLEM

A TOMEI emblem is included for displaying that your car is fitted with a TOMEI short block.